High-strength and process reliability joining of materials

RIVSET® self-pierce riveting is a process for a high strength mechanical joining of similar or combinations of materials whereby several layers can be joined without problem.

ask about this product

Make an inquiryDownloads

|

RIVSET

EN Version |

1.89 MB | pdf

|

Catalogue

|

|

Product descriptions

- Product characteristics

- Installation procedures

- Product types

All manufacturing industry has to join materials together. The importance and use of mechanical joining methods has increased significantly in recent years.

Benefits:

- No pre-drilling

- Especially approvite for hybrid joining

- High dynamic fastness

- Force and form-fit

The trend is towards the use of lightweight assemblies, galvanised and coated steels, high strenght steels, aluminium and plastics and combinations of these materials.

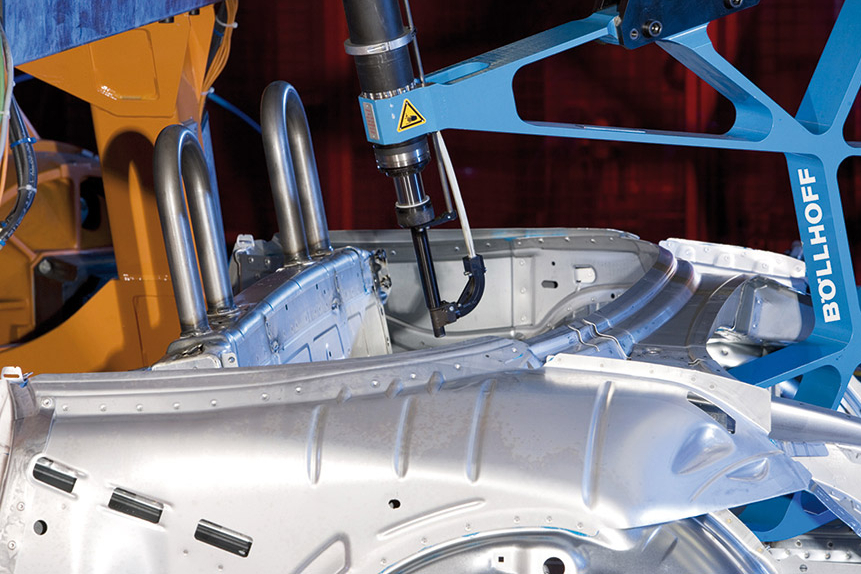

Particularly in the sheet-metal industry, RIVSET® self-pierce riveting has turned out to be very promising as an alternative and/or an addition to the previously dominating joining methods.

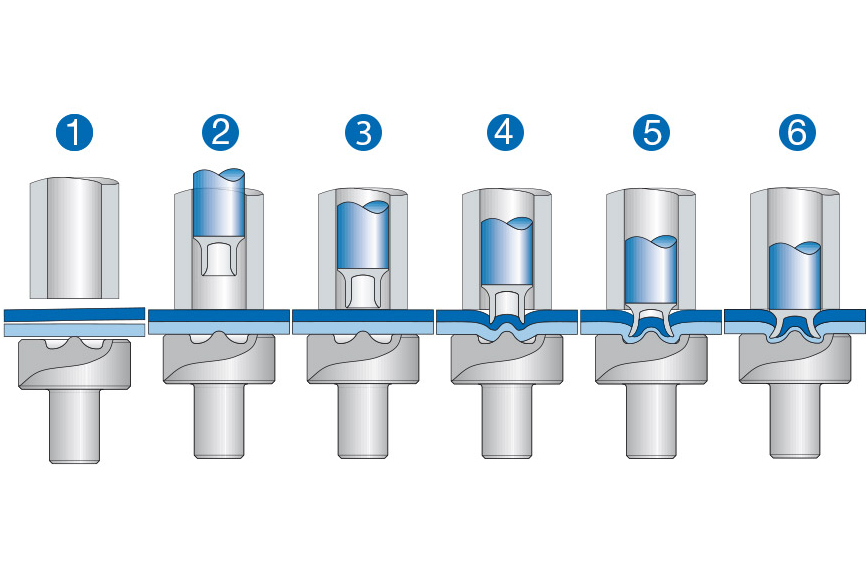

Material layers are joined by a hardened semi-tubular rivet in a single step with no pre-drilling, little noise and no emissions, producing an interlocked friction joint. The rivet is designed to penetrate through the top material and is spread under the influence of a die positioned below the lower material. As this lower material is not pierced the resulting joint is localised and impervious to gas and liquid.

How it works:

- Clamping device

- Punch

- Self-pierce rivet

- Upper workpiece

- Lower workpiece

- Die

RIVSET® self-pierce rivets are exclusively produced in our own production locations and are subject to the strictest quality testing at every stage of production. This is the only way we can satisfy the high demands of our customers.

Rivet by rivet.

The wide variety of possible applications of self-pierce rivets also explains the wide range of variants. RIVSET® self-pierce rivets differ in material, shape, hardness, surface, head shape, shaft length and diameter.

Your application determines the rivet type.