After-moulding insertion into plastic parts bears many benefits:

- Shorter injection cycles and thus lower manufacturing costs for plastic components

- Safe, stress-free anchorage

- High pull-out and torsion values

- Any repeated screwing as opposed to self-forming screws

ask about this product

Make an inquiryDownloads

|

AMTEC

EN Version |

1.27 MB | pdf

|

Catalogue

|

|

Product descriptions

- Product characteristics

- Installation procedures

- Product types

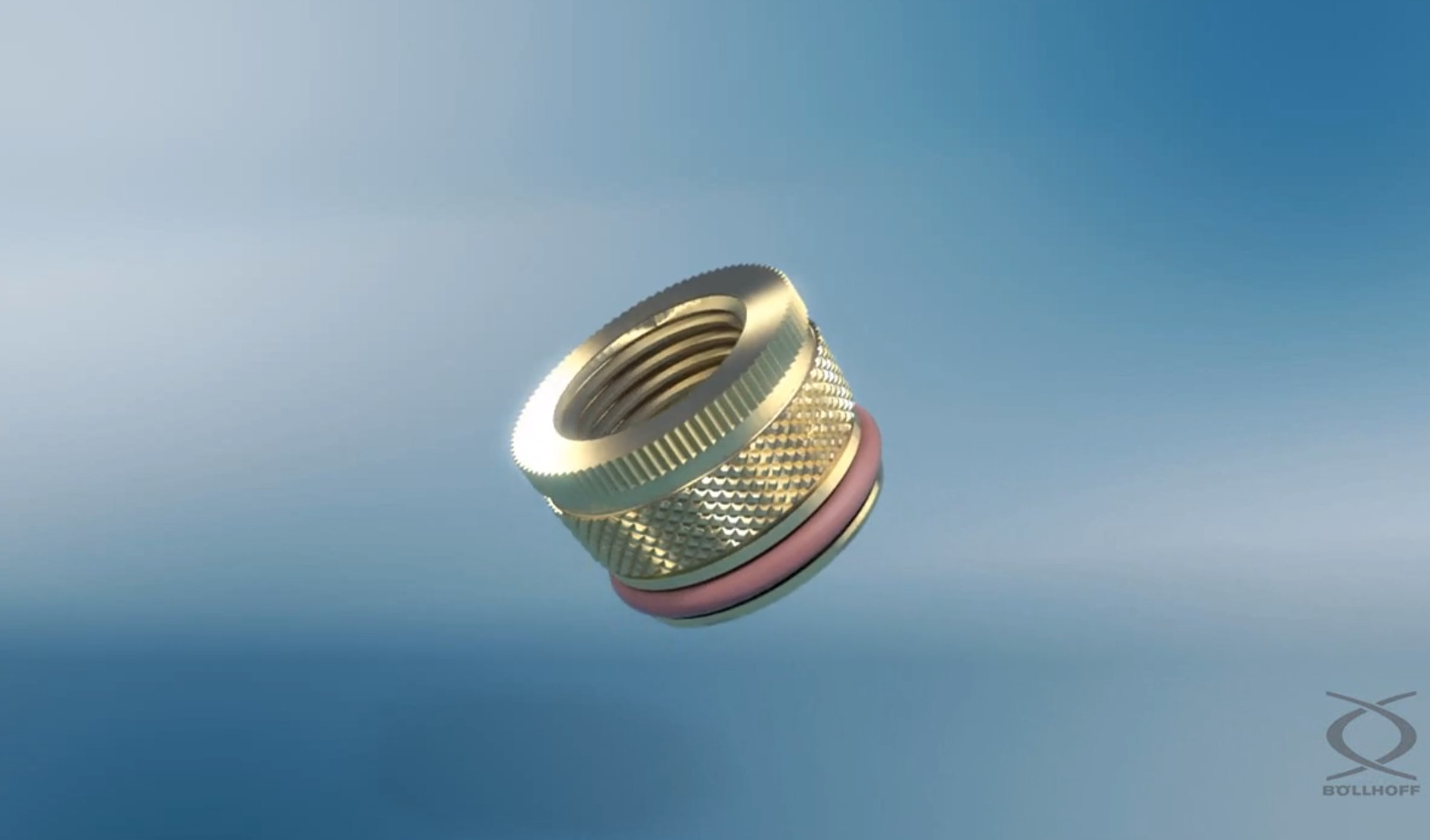

HITSERT® thermal installation

- Ideal for thermoplastic components

- Conical design

- Rational installation due to processing machines ranging from hand tools to fully automatic machines

The HITSERT® thread insert is heated to the melting temperature of the plastic. As a result of the heat transfer upon insertion, the plastic can flow into the undercut of the thread insert. Upon cooling, a low-stress interference is realised.

The HITSERT® 2 thread insert is heated to the melting temperature of the plastic. As a result of the heat transfer upon insertion, the plastic is plasticised for a short time and flows into the undercut of the thread insert. Upon cooling, a low-stress interference is realised.

HITSERT® 3 is a tapered universal insert for thermoplastics (thermal installation, tapping and cold insertion). Owing to its patented external contour (characterised by a fine, self-tapping thread with asymmetric flank profile) HITSERT ® 3 is the first thread insert to be employed for the complete range of well established installation methods. Our Application Engineering Department helps you to find the perfect installation method for your application (in terms of installation effort and fitting values). You set the priorities.

HITSERT 2

The HITSERT® 2 thread insert is heated to the melting temperature of the plastic. As a result of the heat transfer upon insertion, the plastic is plasticised for a short time and flows into the undercut of the thread insert. Upon cooling, a low-stress interference is realised.

The advantages

- Ideal for thermoplastic parts

- Especially designed for thermal installation

- Screw-locked and low-tension anchoring

- High pull-out values

- Efficient installation due to single-spindle, multiplespindle or automatic machines with preheating device

Material: Cu Zn 38 Pb 2 (EU 2000/53 compliant)

HITSERT 3

HITSERT® 3 is a tapered universal insert for thermoplastics (thermal installation, tapping and cold insertion). Owing to its patented external contour (characterised by a fine, self-tapping thread with asymmetric flank profile) HITSERT ® 3 is the first thread insert to be employed for the complete range of well established installation methods. Our Application Engineering Department helps you to find the perfect installation method for your application (in terms of installation effort and fitting values). You set the priorities.

The advantages

- Well-proven 8° taper angle

- Self-centring

- Large contact surface for plastic prior to installation

- Flexible installation due to thermal installation, tapping or cold insertion

- Short installation times

- Milled external contour (low tolerances)

- Efficient seal inserts