Precote® products are used in most industries:

- automotive and tier level 1 supplier industry

- aeronautic engineering

- railway vehicle manufacturing

- plant and mechanical engineering

- domestic appliances and electronics industry

- countless customized solutions for a wide choice of further applications

ask about this product

Make an inquiryDownloads

|

Precote

EN Version |

1.23 MB | pdf

|

Catalogue

|

|

|

Chemical thread retention methods

EN Version |

308.90 KB | pdf

|

Catalogue

|

|

Product descriptions

- Product characteristics

- Installation procedures

- Product types

• Extreme locking effect under dynamic loading

• Reliable sealing by coating the entire circumference of the thread

• Consistent assembly values due to homogenous application of material

• Application on almost every type of surface

• Excellent thermal resistance

• Excellent chemical resistance

• Inhibiting corrosion

• Inseparable connection of screw and locking element, i.e. the lokking element cannot get lost or be forgotten

• Physiologically safe

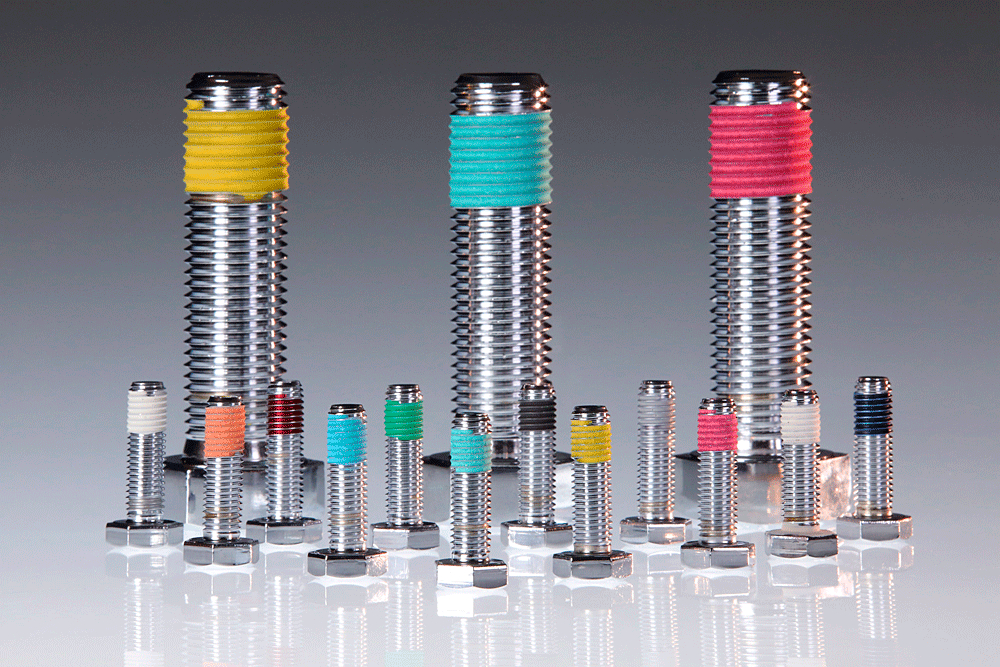

Precote® products offer optimal solutions for locking and sealing as well as controlled assembly and disassembly. These specially developed products designed for the pre-coating of threads are based on our unique microencapsulation technology enabling us to offer many advantages over conventional adhesives. The pre-coated adhesive is inactive and dry to the touch until the coated fastener is used. During assembly the adhesive is activated. Able to cure quickly at room temperature, precote® coating provides a reliable locking and sealing function.

Locking

Precote cures within a short time after assembly to provide reliable locking performance even at highest temperatures and transverse loads.

Sealing

Precote completely fills the thread gap, thereby achieving the required sealing effect.

Assembly

Precote ensures uniform assembly values by optimum friction coefficients.

Disassembly

Precote enables an easy, non-destructive disassembly, even after long periods and high thermal loads.