Safe adhesion without loss of performance

ONSERT® technology allows adhesion of different fasteners to diverse materials.

ask about this product

Make an inquiryDownloads

|

ONSERT

EN Version |

603.49 KB | pdf

|

Catalogue

|

|

Product descriptions

- Product characteristics

- Installation procedures

- Product types

An efficient connection

Böllhoff, as a specialist in mechanical joining technology, and DELO, as a specialist for intelligent bonding technology, have together developed a new fastening system.

It’s the ONSERT® technology – quick bonding of fasteners without loss of performance.

Your benefits:

- Optimised design ensures distortion-free surfaces; ideal where close tolerance or visual requirements are important. Fastening elements do not become apparent on the visible side through

- Heat input such as it happens during welding and heat curing

- Processing parameters independent of customer component

- Full mechanical load capacity immediately after irradiation (no post-crosslinking)

- Short curing times (< 5 sec)

Adhesives

There are two product families in the DELO range of adhesive products that are suitable for ONSERT® adhesion.

DELO-PHOTOBOND

Light-curing acrylate

Curing in less than 10 seconds

Universal adhesion to various substrates

Application specific mechanical properties (ultimate elongation, TG, Young’s modulus)

DELO-DUALBOND

2K-acrylate plus light curing

Fixing by light in 4 seconds, technical strength after 60 minutes

Temperature range from -40 °C to +120 °C

Bonding process

- Dispensing

- Joining

- Curing

ONSERT® – The product range

ONSERT® basic – surface connection

A transparent plastic sheath is applied to fasteners. The geometry provides for sufficient bonding surface.

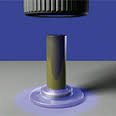

ONSERT® plus – ripp connection

The fastening elements are over moulded with transparent plastic (adhesive dome) and are then fitted using light-curing adhesive. Adhesive domes can be produced in various designs, e.g. with internal threads, bolt threads, ball studs or snap connections.