QUICKSERT® – thread inserts for self-tapping insertion

After-moulding insertion into plastic parts bears many benefits:

- Shorter injection cycles and thus lower manufacturing costs for plastic components

- Safe, stress-free anchorage

- High pull-out and torsion values

- Any repeated screwing as opposed to self-forming screws

ask about this product

Make an inquiryDownloads

|

AMTEC

EN Version |

1.27 MB | pdf

|

Catalogue

|

|

Product descriptions

- Product characteristics

- Installation procedures

- Product types

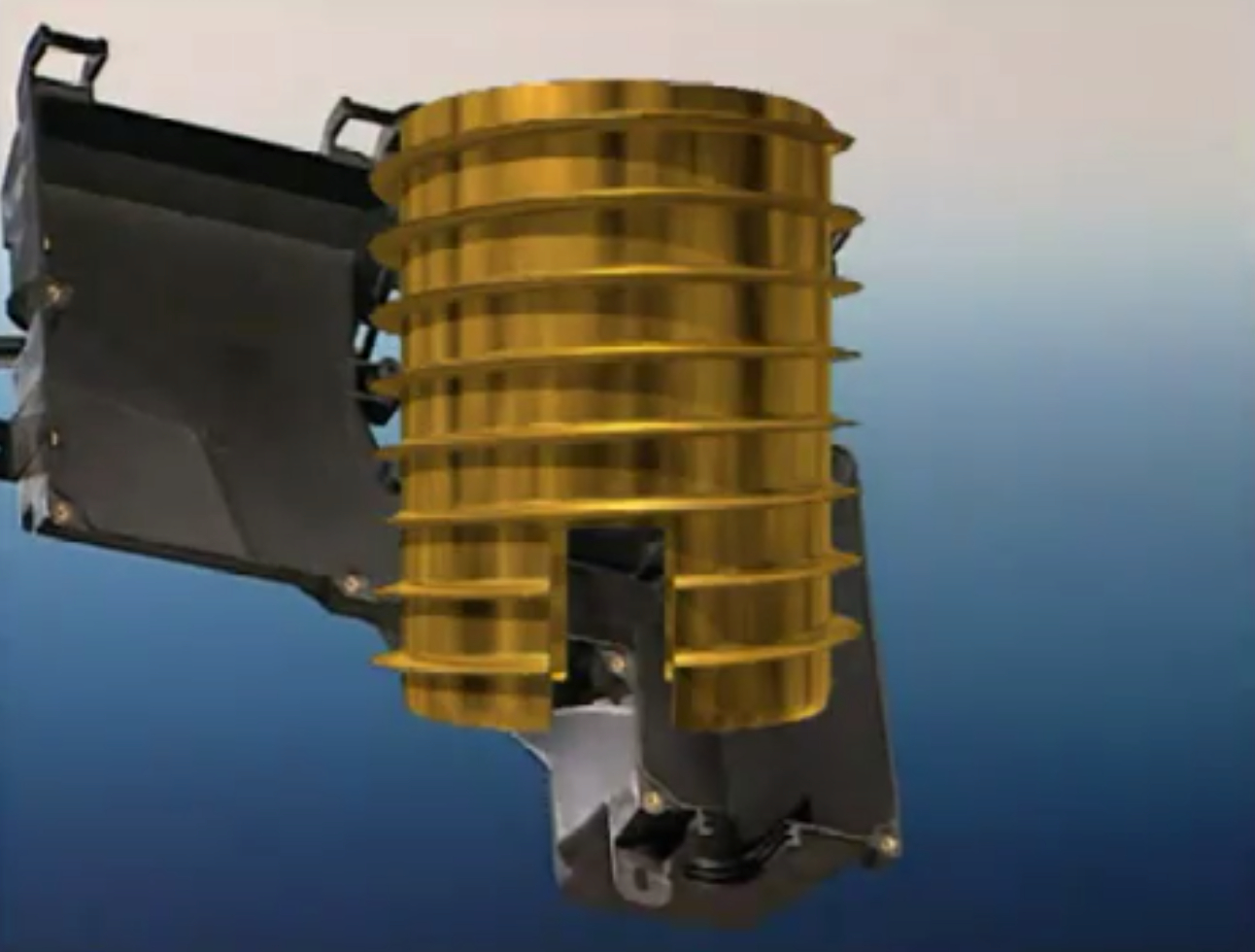

QUICKSERT® self-tapping insertion

- Ideal for brittle and ductile plastics and glass-fibre reinforced thermoplastics

- Variant with or without flange

- Self-tapping insertion with rotating mandrel

- QUICKSERT® hex variant with hexagon socket for even more efficient insertion

QUICKSERT® consists of a cylindrical basic body with internal thread and a special external thread. The profile of the external thread has an extremely small flank angle and expands asymmetrically towards the thread root. This way, installation at low driving torques is optimised.

Very good tight-fit is achieved with an ideal distribution of load. The bottom part of the bush is provided with a cutting slot. For special requirements, we offer a version with flange. The threaded bush is screwed in with a rotating spindle.

QUICKSERT® Hex consists of a cylindrical basic body with internal thread and additional internal hexagon and a special external thread. The profile of the external thread has an extremely small flank angle and expands asymmetrically towards the thread root. This way, installation at low driving torques is optimised. Very good tight-fit is achieved with an ideal distribution of load.

The threaded bush is inserted and screwed in with a rotating spindle.

It is not necessary to screw out the spindle.

QUICKSERT® Plus consists of a tapered basic body (8° overall taper) with internal thread, additional internal hexagon and a special external thread.

The profile of the external thread has an extremely small flank angle and expands asymmetrically towards the thread root. Driving torques for installation are thus reduced. Very good tight-fit is achieved with an ideal distribution of load. Since no cutting slot is required, there is no chip formation because the thread insert forms into the plastic material.

For special requirements, we offer a version with flange.

The threaded bush is inserted and screwed in with a rotating spindle.

Quicksert

QUICKSERT® consists of a cylindrical basic body with internal thread and a special external thread. The profile of the external thread has an extremely small flank angle and expands asymmetrically towards the thread root. This way, installation at low driving torques is optimised. Very good tight-fit is achieved with an ideal distribution of load. The bottom part of the bush is provided with a cutting slot. For special requirements, we offer a version with flange. The threaded bush is screwed in with a rotating spindle.

The advantages

- For brittle and ductile plastics such as unsaturated polyester resins (SMC, ZMC), polyurethane and glass-fibre reinforced thermoplastics

- Universal use

- High-strength and torsion-proof threads

- Optimum assembly characteristics

Material: 1.0718 11 SMnPb 30 zinc coated, chromated

or Cu Zn 38 Pb 2 (EU 2000/53 compliant)

Quicksert Hex

QUICKSERT® Hex consists of a cylindrical basic body with internal thread and additional internal hexagon and a special external thread. The profile of the external thread has an extremely small flank angle and expands asymmetrically towards the thread root. This way, installation at low driving torques is optimised. Very good tight-fit is achieved with an ideal distribution of load. The bottom part of the bush is provided with a cutting slot. For special requirements, we offer a version with flange. The threaded bush is inserted and screwed in with a rotating spindle. It is not necessary to screw out the spindle.

The advantages

- Efficient installation process resulting from additional driver shape (e.g. hexagonal shape)

- For thermoplastics and thermosets

- Extra small flank angles of the special external thread minimise radial tensions

- High-strength and torsion-proof threads

- Special version available with external left-hand thread for improved reverse locking

Quicksert PLUS

QUICKSERT® Plus consists of a tapered basic body (8° overall taper) with internal thread, additional internal hexagon and a special external thread. The profile of the external thread has an extremely small flank angle and expands asymmetrically towards the thread root. Driving torques for installation are thus reduced. Very good tight-fit is achieved with an ideal distribution of load. Since no cutting slot is required, there is no chip formation because the thread insert forms into the plastic material. For special requirements, we offer a version with flange. The threaded bush is inserted and screwed in with a rotating spindle.

The advantages

- Suitable for thermoplastic parts

- High-strength and torsion-proof threads

- Chipless installation

- Special version available with external left-hand thread for improved reverse locking

Material: Cu Zn 38 Pb 2 (EU 2000/53 compliant)

QUICKSERT EXPANSION TYPE

The QUICKSERT® Expansion is spun on to the rotating threaded mandrel of the installation tool and introduced into the mounting hole. The hole can be preformed or machined with common drills as a blind or through hole. The axial pulling motion of the threaded mandrel causes the QUICKSERT® Expansion Expansion to shear at the predetermined breaking point between anchoring sleeve and threaded bush. The threaded bush is pulled into the anchoring sleeve and expands it. Meanwhile, the diamond knurl of the anchoring sleeve is pressed into the wall of the hole. The thread insert is now anchored and locked against screwing and pull-out.

The advantages

- No tapping

- Quick, cost-effective installation

- Chipping-free installation in smooth mounting holes

- High-strength threads in light metals

- High-strength threads in thermoplastic and thermoset components** after moulding of components

- Suitable for one-sided accessibility of the installation point

- For screwed connections that can be detached as often as required

- For installation on finished surfaces

Material: 11 SMn Pb 30+c

Surface: A2J ISO 4042 Cr (VI)-free or Cu Zn 38 Pb 2 (EU 2000/53 compliant)