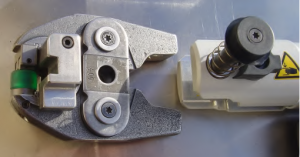

Clinching is a punching and squeezing operation that creates a rivet-like joint between profile and sheet material and the punch and die in framing.

ask about this product

Make an inquiryDownloads

|

Clinch Partner Euro Global

EN Version |

148.23 KB | pdf

|

Catalogue

|

|

|

Clinch Partner Tech

EN Version |

1.05 MB | pdf

|

Catalogue

|

|

|

Clinch Partner Strength Data

EN Version |

35.88 KB | pdf

|

Brochure

|

|

Product descriptions

- Product characteristics

- Installation procedures

- Product types

Advantages :

• No fasteners to buy, sort and feed

• No protruding screw head that may crack gypsum

boards

• No sharp tips that may cause hand injuries

• Speed, 1-2 seconds only

• No damage to galvanizing, paint or coatings

• Conserved corrosion protection

• Possibility of joining more than two layers

• Possibility for intermediate layers for sealing and

sound damping, for example on floor joists

• Possibility of joining layers with different thickness,

like a hold-down to a punch

This is clinching :

In clinching, a rivet-like joint is made from the punch and die themselves without any added fastener. In short, the process is that a punch will push the overlapping material into a die. At the bottom of the die is an anvil so the material will be squeezed between the punch and the anvil to form the clinch joint. The process is fast, clean and silent. The strength of a clinched joint is comparable to that of a rivet or screw and is greater than that of a pin. Our clinch joints have successfully passed tests simulating earthquakes, strong winds and fire and are approved for load-bearing structures in all seismic zones, including zones 3 and 4.

The product range goes from ultra-light stitchfolding tools and light handheld clinching tools, to heavy-duty clinching tools and and clinching workheads for line builders and integrators.

TAGGER – Stitchfolding tools

TAGGER creates a staple-like joint from the material members, without any added fasteners. The stitchfolding process is fast, clean and silent.

Light-weight clinching tools

Application areas include appliances, metallic furniture, internal partition walls, HVAC, solar panels etc.

Heavy-duty clinching tools

Application areas include truck beds, superstructures, heat exchangers, air conditioning equipment etc.

The Mega line

The Mega line features articulated machines to be used hand-held, pillar or bench mounted, or robot-held. The automated opening/closing mechanism allows production rates of the order of 5,000-7,000 clinch points per 8-hour shift or more than 1-1.3 million joints per year.

The Kombi line

The Kombi line offers a selection of fixed and articulated workheads. Here, integrators and line builders find solutions for even the most demanding clinching jobs. Workhead depths from 35 mm, 1 1/2″ to 300 mm, 12″, greater on special request.