Systems for stepless tolerance compensation.

FLEXITOL® tolerance compensation systems were developed to compensate tolerances with economical assembly solutions and thus ensure a safe sequence in series production.

ask about this product

Make an inquiryDownloads

|

FLEXITOL

EN Version |

1.93 MB | pdf

|

Catalogue

|

|

Product descriptions

- Product characteristics

- Installation procedures

- Product types

Not only in the automotive industry do production processes based on modular construction succeed.

Here, individual components are supplied to the assembler where they only have to be assembled.

To ensure flawless series production certain tolerances are assumed. The automatic tolerance compensation system FLEXITOL® provides a technically and economically optimised solution.

Your benefits:

- Compensation of wide tolerances

- High performance reliability

- Access from one side only

- Easily integrates into a variety of applications

- High end product quality

- Fast and easy installation

Manual and automatic tolerance compensation system

Today we have manual and automatic tolerance compensation systems. Use of one or other depends on the field of application. When positioning a component in an assembly without any auxiliaries, then manual solutions are considered most appropriate. For a component spacing predefined by a preceding step, then we would rather recommend automatic solutions.

However, manual and automatic tolerance compensation systems may also be combined.

Manual tolerance compensation:

The tolerance compensation system is screwed into the receiving parts to a defined position. During screwingin, the component tolerances can be compensated (Zero tolerance at delivery of the component).

Further alignment is possible during installation. The adjusted position is maintained when the joint is loosened.

Automatic tolerance compensation:

Two components are aligned / positioned toward each other. During screwing, the spacing between both components is automatically adjusted. The tolerance compensation system fixes the originally aligned position. If the joint is loosened, the system resumes the initial position.

Currently, there are four FLEXITOL® types.

Different ranges of use present different requirements and require application-optimised tolerance compensation systems.

FLEXITOL® metal

The two-piece system is highly wear-resistant and can very well be retrofitted. Manual adjustment for re-adjustment is possible as well. The adjustment element can also be installed in solid material.

The fastening element is available in different designs.

Assembly is easy due to approved blind rivet technology.

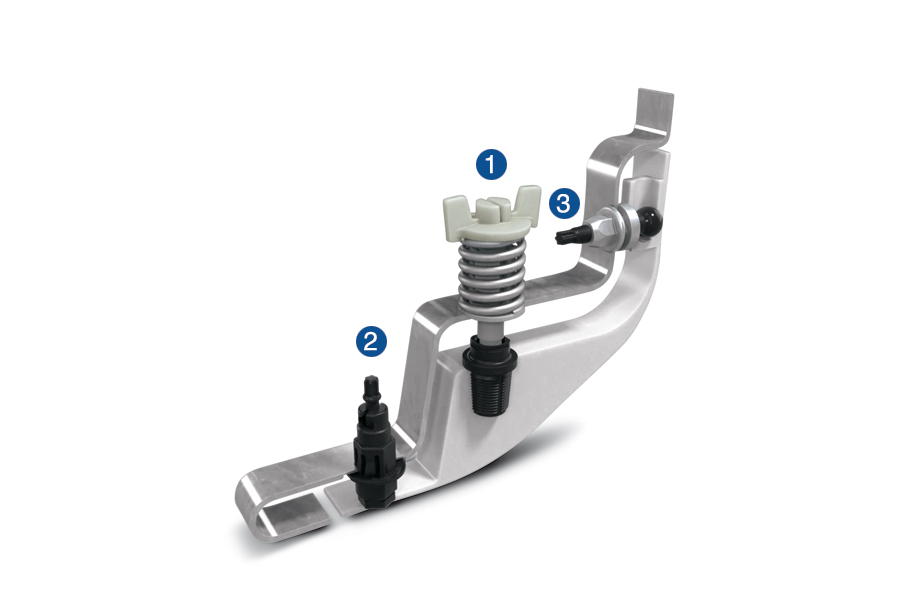

FLEXITOL® hybrid

FLEXITOL® hybrid is a multi-component system mainly designed for use in large-scale production. Due to its modular construction, a variation of different inserted heights and tolerance compensation dimensions may easily be implemented.

To ensure high force transmission, the force transmitting components are made of metal. They are enclosed by a nut cage made of plastic.

Fastening is executed via the integrated blind rivet nut which can also be replaced with alternative connections (e. g. clips).

FLEXITOL® plastic

The FLEXITOL® plastic consists of a plastic adjustment element and a plastic fastening element and is supplied as a pre-assembled assembly.

This assembly should be screwed into the mounting hole in the plastic receiving part. A bayonet variant offers another way to attach the basic element. The FLEXITOL® plastic is then inserted into a keyhole-shaped receiving opening and locked with a quarter turn. The subsequent installation is the same as for the self-tapping variant. Depending on the version, a self-tapping metal screw or a metric screw can be used as fastening screw.

FLEXITOL® K’ in K’

Example of the banjo screw

For “banjo screws”, the function of the K’ in K’ thread is extremely important.

The K’ in K’ thread creates its mounting thread into the existing plastic bore hole. Due to a resistance effect, the banjo screw can then only be screwed further in or out with a higher torque. We can offer different variants according to your requirements.