Manufactured from high quality chromium nickel stainless steel, PowerCoil Wire Thread Inserts provide high strength internal threads that resist the effects of temperature and corrosion. Their unique design ensures superior threads whose compound performance cannot be reproduced by any other single fastening method. Available in two basic forms, free running or screw locking, they are much lighter and less expensive than any other equivalent type of thread insert and because of their compact size they can generally be incorporated into existing designs where no previous provision has been made.

ask about this product

Make an inquiryDownloads

|

Powercoil_1

en, fr, de Version |

9.65 MB | pdf

|

Catalogue

|

|

|

Powercoil_2

EN Version |

6.58 MB | pdf

|

Catalogue

|

|

|

PowerCoil - flyer

EN Version |

1.13 MB | pdf

|

Leaflet

|

|

|

Prothread

EN Version |

8.71 MB | pdf

|

Catalogue

|

|

|

ON THE ROAD

EN Version |

5.34 MB | pdf

|

Catalogue

|

|

Product descriptions

- Product characteristics

- Installation procedures

- Product types

PowerCoil Wire Thread Inserts strengthen tapped threads in light weight parent materials such as aluminium. They are helically wound inserts made from high quality chromium nickel stainless steel with a diamond shaped cross section.

Most importantly, PowerCoil inserts allow the stress loading from the bolt or similar threaded part to be more evenly distributed over the threads in the parent material.

In addition to PowerCoils standard ‘free running’ inserts, ‘screw locking’ inserts are also available. These inserts have polygonal grip coils within the length of the insert which exert radial pressure on the male thread, thereby gripping the bolt and preventing it from loosening under vibration or impact.

In addition to stainless steel, PowerCoil inserts can be made from Phosphor Bronze, Inconel or Nimonic 90 depending on the application. They can also be supplied with different surface fi nishes and coatings including cadmium, siver and zinc plating and dry film lubricant. A complete range of Screw Thread Insert (STI) taps are available as well as low, medium and high volume installation tools and a wide range of individual and workshop.

Powercoil Screw Thread Inserts:

- Increase quality and performance whilst reducing overall product cost.

- Create internal threads in which wear due to thread friction is virtually eliminated. Useful in applications where repeated assembly & disassembly is required.

- Protect tapped threads against failures due to stripping, seizing, corrosion and wear.

- Create internal threads with greatly improved distribution of residual stress loading.

- Compensate for pitch and flank angle errors.

- Can generally be introduced into existing designs where no previous provision has been made.

- Make it possible to use thinner sections or lighter parent materials without sacrificing thread strength.

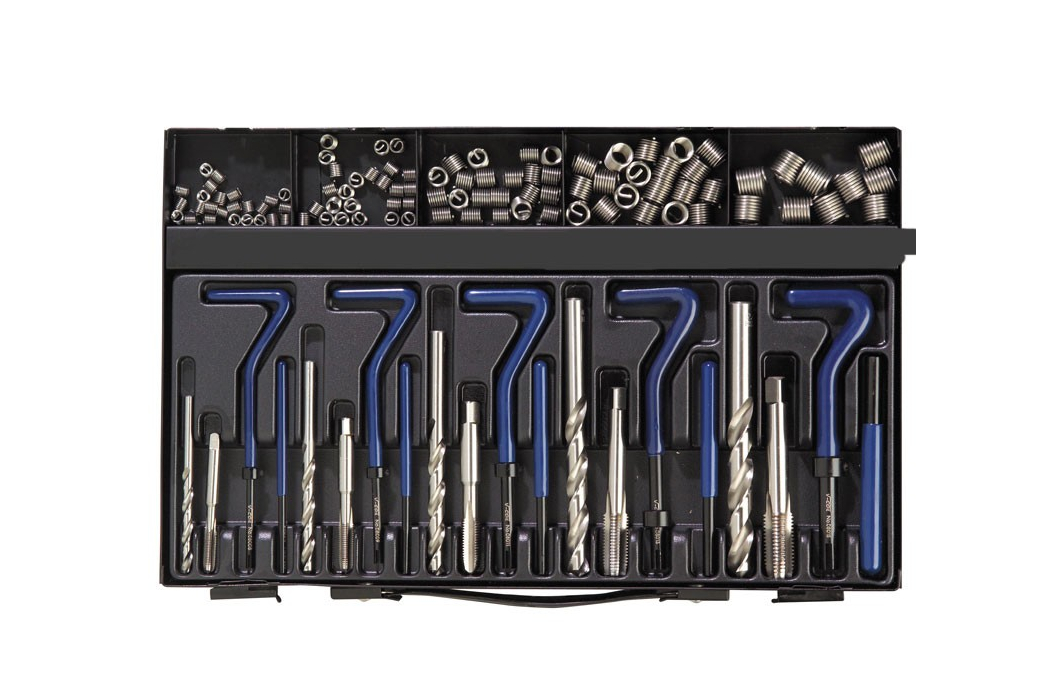

PowerCoil Thread Repair Kits

M2 – M12 (1/8″ – 1/2″) PowerCoil Thread Repair Kits include all the necessary components to successfully repair damaged threads. Kits include Drill, STI Tap, Inserts, Installation Tool and Tang Break-Off Tool. The PowerCoil Wire Thread Insert System includes a complete range of over 140 Thread Repair Kits; Free Running & Screw Locking inserts; Strip Feed Inserts; STI Hand & Machine Taps; Installation, Tang Break & Removal Tools

features & benefits

- Lighter and Cheaper than any other equivalent type of thread insert.

- Can generally be introduced into existing designs where no previous provision has been made.

- Increase quality and performance whilst reducing overall product cost.

- Providing threads that stay tight.

- Their introduction may result in the use of thinner sections or lighter parent materials without sacrificing thread strength.

- Create internal threads with greatly improved distribution of residual stress loading

- Compensate for pitch and flank angle errors

- Create internal threads in which wear due to thread friction is virtually eliminated.

Loksert

Loksert solid keylocking inserts are an easily installed thread assembly that is ideal for replacing damaged or worn threads in virtually any material – ferrous, non-ferrous and non-metallic. they are constructed from high quality carbon steel or extremely hard wearing stainless steel. One piece loksert inserts are supplied with the dove-tailed locking keys pre-assembled. Lokserts are suitable for repairing and creating threads in a wide range of applications including forgings and castings and are especially suited to situations that experience heavy wear and vibration – such as mining, construction and earthmoving equipment.

features & benefits

- Solid bushing utilising locking keys provides positive mechanical lock against rotation

- High strength and reliability provides maximum pullout strength

- Installed using standard drills and taps

- Simple installation – no special skills required

- Suitable for use in a wide range of parent materials

- Impossible to cross thread during installation

- Simple removal process if required

- No tang to break and remove

- Available in metric sizes, inch sizes and spark plug sizes

- Available in thinwall and Heavy duty.

Tapsert

Tapserts are self cutting threaded inserts that feature both external and internal threads. they are driven into a pre-formed or pre-drilled retaining hole and the cutting slots (or cutting bores) effectively tap the hole as the insert is wound into the parent material. tapserts are available in case hardened steel or stainless steel.

Tapserts are ideal for use in low shear strength materials (such as alloys, plastics and castings) which require threaded seats with high load capacity and wear resistance.

features & benefits

- High pull-out strength

- High loading capacity in low shear strength materials

- Wear free, vibration resistant screw joint

- Pre-cast or pre-drilled holes with standard tolerance

- No requirement for expensive thread tapping tools

- Retains and captures chips from installation in chipping reservoirs.